Latest Developments and Trends in Battery Technology

2025 has emerged as a pivotal year for battery technology, marked by breakthroughs spanning material science, structural innovation, and industrialization. Driven by the dual demands of electrified transportation and grid decarbonization, the industry is transitioning from “single-technology dominance” to “multi-core architecture,” reshaping the landscape of energy storage. This article dissects the most significant advancements and future trajectories defining the sector.

Core Technological Breakthroughs in 2025

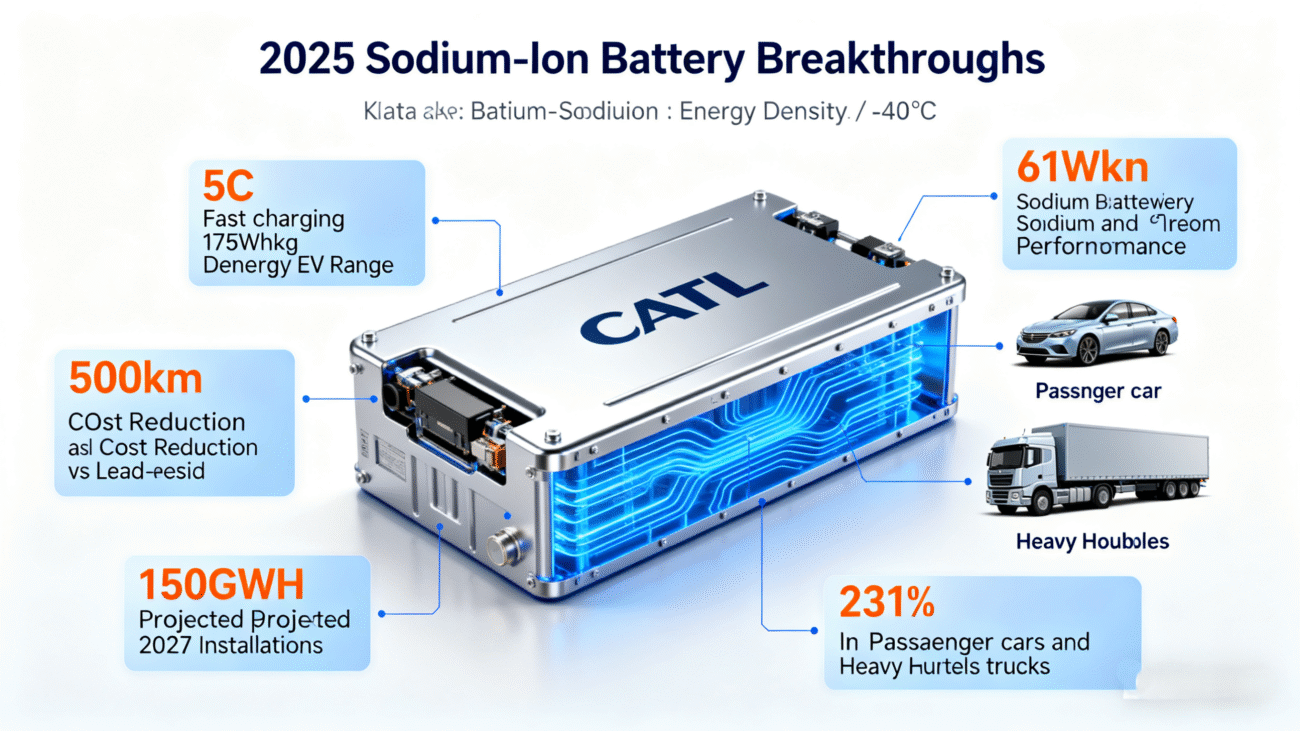

Sodium-Ion Batteries: From Niche to Mass Adoption

Sodium-ion batteries have shattered longstanding limitations of low energy density and poor low-temperature performance. CATL’s newly launched sodium battery achieves 175Wh/kg energy density and maintains 90% capacity at -40°C, thanks to atomic-level material innovations including composite anti-freeze electrolytes and nano-structured electrodes . This breakthrough enables practical applications across multiple segments: passenger car versions support 5C fast charging and 500km range, while 24V heavy-duty truck batteries deliver an 8-year lifespan and 61% cost reduction compared to lead-acid alternatives. With production lines operational in Fujian and Germany, sodium-ion batteries are projected to replace 60% of heavy truck starter batteries by year-end and reach 150GWh global installations by 2027 .

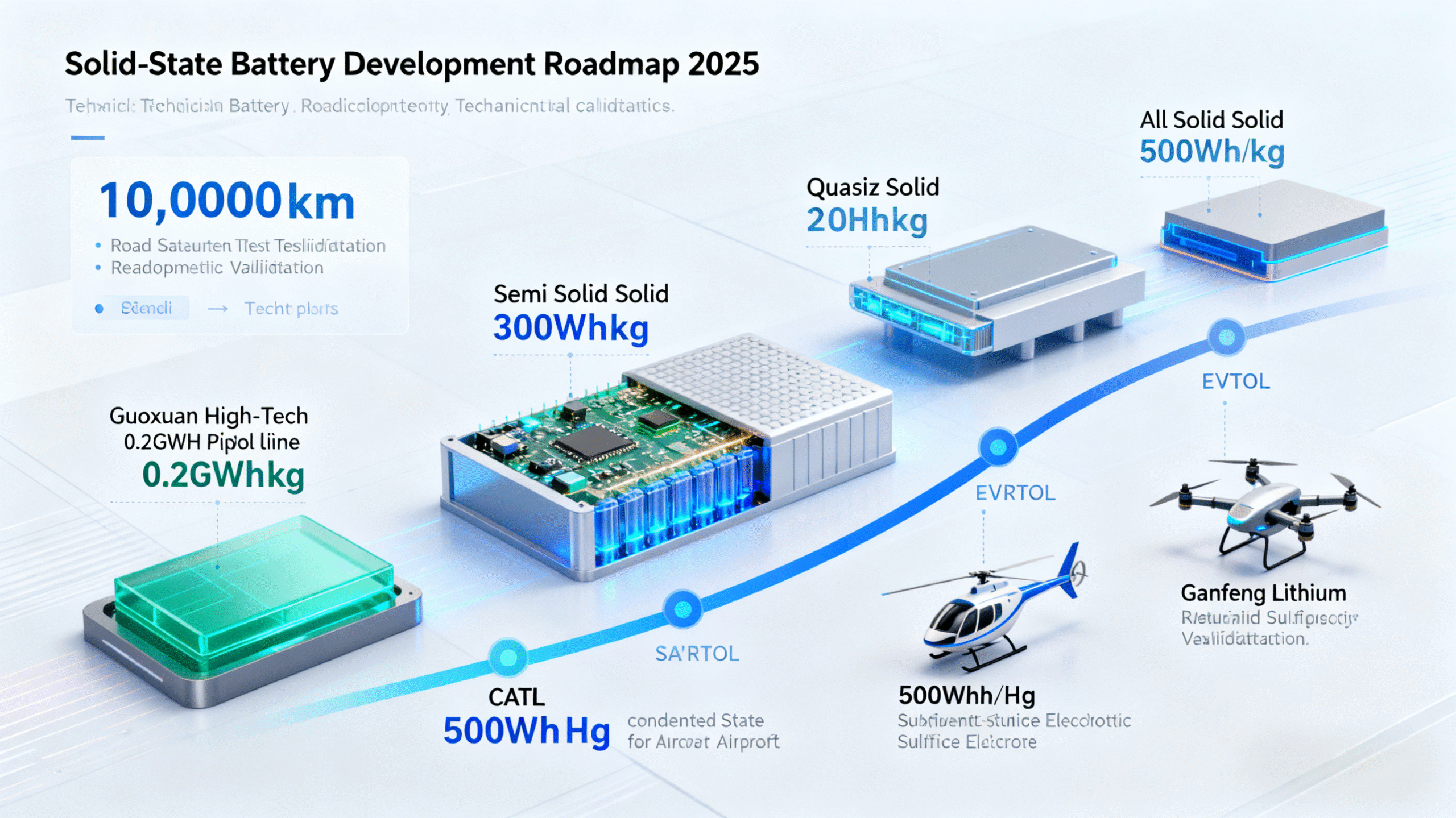

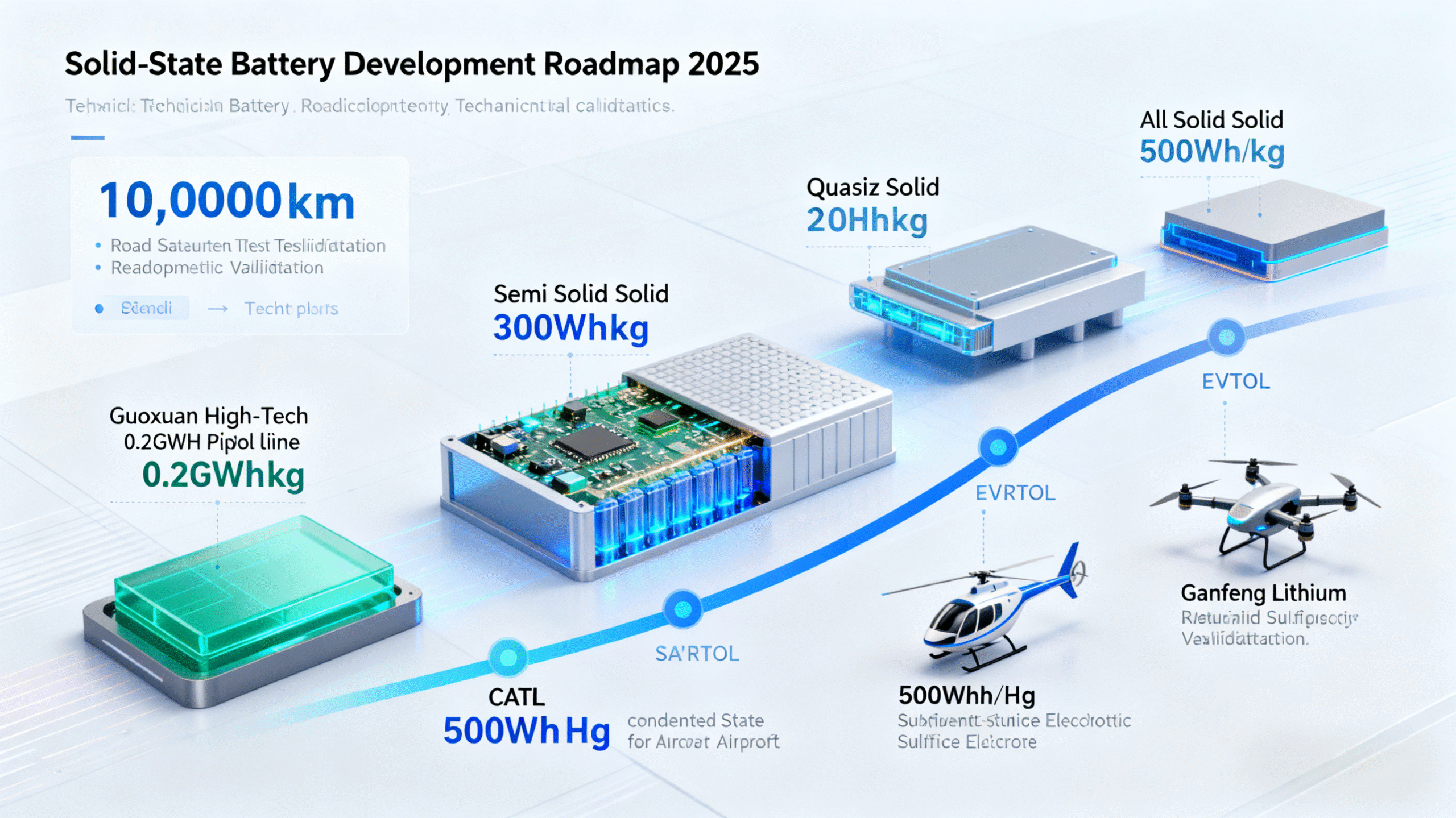

Solid-State Batteries: Accelerating Industrialization

The race toward solid-state battery commercialization has entered its final lap. At CIBF2025, industry leaders showcased tangible progress along the “semi-solid → quasi-solid → all-solid” roadmap. Guoxuan High-Tech has commissioned a 0.2GWh all-solid-state battery pilot line with 100% domestically developed equipment, achieving 90% yield and initiating vehicle road tests . Its G-Yuan quasi-solid-state battery, boasting 300Wh/kg energy density and 10,000km road test validation, maintains “no fire, no explosion” performance even when pierced by 3mm steel needles . CATL’s condensed-state semi-solid battery hits 500Wh/kg, advancing collaboration on electric aircraft projects, while Ganfeng Lithium has begun small-batch production of 500Wh/kg all-solid-state batteries with sulfide electrolytes for eVTOL applications .

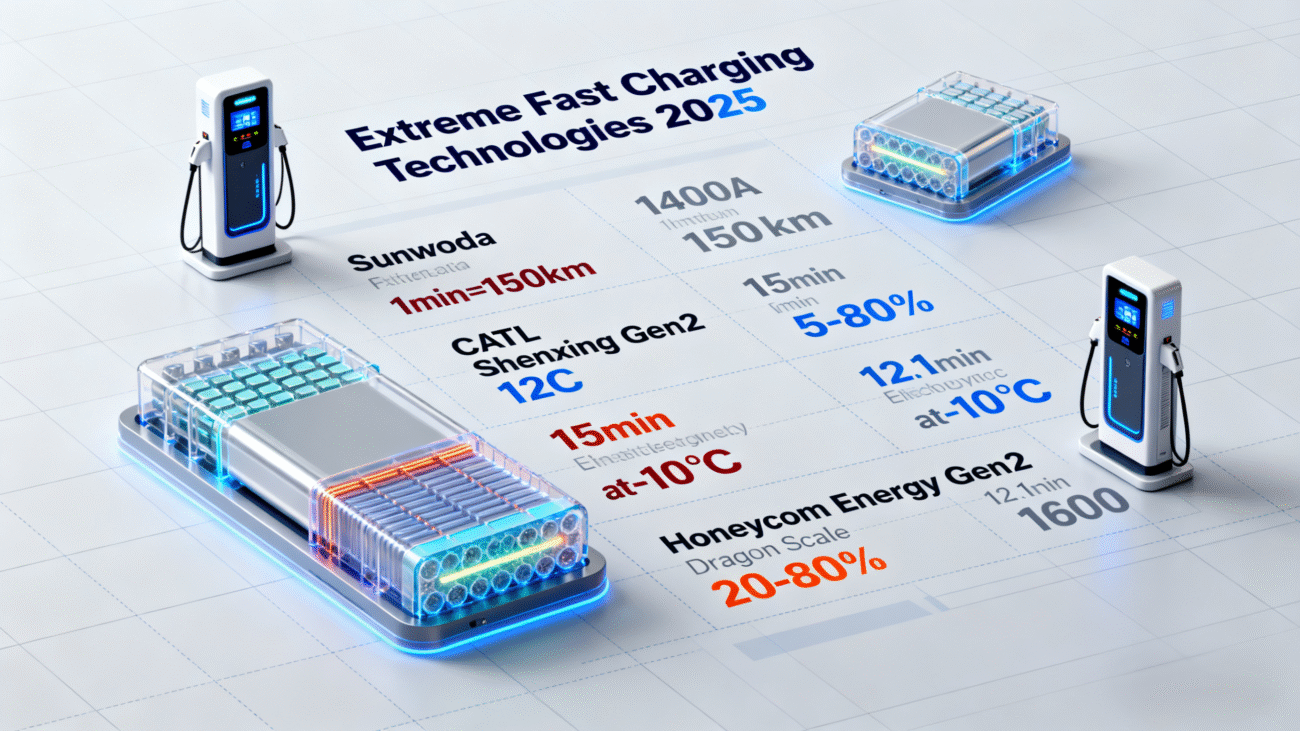

Fast-Charging Technology: Matching Fueling Speed

“Extreme Fast Charging (XFC)” has become the new battlefield for technical competition, targeting parity with gasoline refueling. Sunwoda’s “Xinxingchi 2.0” battery employs dual-gradient electrodes (coarse-grain cathodes and porous carbon anodes) to deliver 1400A fast charging, adding 150km range in just one minute . CATL’s second-generation Shenxing supercharged battery achieves 12C charging, replenishing 5-80% capacity in 15 minutes at -10°C and maintaining 600kW power output even at 20% state of charge . Honeycomb Energy’s second-generation “Dragon Scale” battery, launching in mid-2025, completes 20-80% charging in 12.1 minutes with over 1600 charge cycles .

Large-Format Cells: Scaling Up for Energy Storage

The energy storage sector is entering the “600Ah+ era” as large-format cells drive down levelized cost of storage (LCOS). Rupo Lanjun’s 587Ah storage cell reaches 430Wh/L energy density with 10,000 cycles and 25-year lifespan, boosting system efficiency to 96.5% . Sunwoda’s 625Ah “Xinyue” cell features a thermoelectric separation design that contains thermal runaway through directional pressure relief, while its space utilization is improved by 30% . For cylindrical formats, multifunctional 60-series cells (60180 model) offer 65Ah capacity and 180Wh/kg energy density, with dual explosion-proof design and can-shaped structure enabling cost advantages for utility-scale storage .

Paradigm Shift in R&D: AI-Powered Acceleration

Artificial intelligence and supercomputing are revolutionizing battery development cycles. Argonne National Laboratory has integrated its upgraded Advanced Photon Source (APS) – with 500x brighter X-ray beams – and Aurora exascale supercomputer to create an autonomous R&D loop . This system enables real-time observation of atomic-level changes during battery operation, with Aurora processing over 100 petabytes of annual data via 1-terabit/s high-speed networks. Machine learning models like PtychoNN and AuroraGPT accelerate material optimization, slashing development timelines from years to days or weeks . This breakthrough is critical for advancing next-generation materials, from high-conductivity electrolytes to lithium-metal anodes.

Expanding Application Ecosystems

Battery technology is increasingly tailored to vertical market needs through scenario-specific innovation:

- Automotive: Dual-core battery architectures combine sodium-ion and lithium-iron-phosphate cells to improve winter range by 35% in northern markets, while high-performance ternary dual-core variants deliver 1500km range and 2.5-second 0-100km/h acceleration .

- Micro-mobility: BYD’s 46120 cylindrical lithium-iron-phosphate battery offers 8-10 year lifespan for electric two-wheelers, with 2000 charge cycles and 5-year warranty .

- Aerospace: 500Wh/kg high-energy-density batteries are entering eVTOL and electric aircraft validation, requiring aviation-grade safety certification .

- Heavy-Duty: Guoxuan High-Tech’s 12-year lifespan heavy truck battery pack and CATL’s sodium-based starter battery address commercial vehicle durability demands .

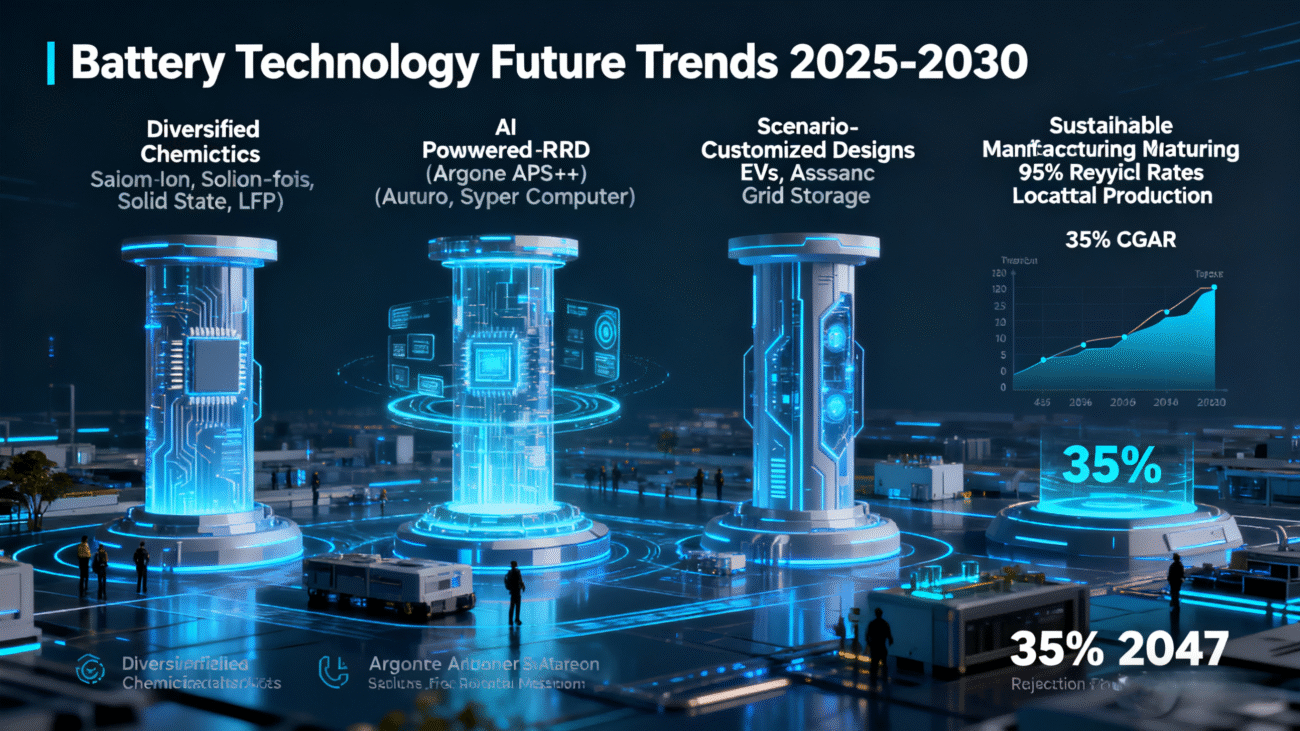

Future Trends and Outlook

1. Diversified Technical Routes

The industry will move beyond lithium-ion hegemony toward a multi-chemistry ecosystem. Sodium-ion batteries will capture low-to-mid-end EV and stationary storage markets, while solid-state batteries target premium automotive and aviation sectors. Lithium-iron-phosphate will retain dominance in mainstream EVs through continuous energy density improvements (targeting 300Wh/kg by 2027).

2. Intelligent and Safe Design

Dual-core redundant architectures and AI-powered BMS will become standard for high-end applications, enabling “single-zone failure protection” and 30-minute emergency power supply for autonomous driving systems . Thermal management innovations and intrinsic safety materials will reduce thermal runaway risks by over 70% compared to 2023 levels.

3. Scenario-Customized Innovation

Batteries will be increasingly designed for specific operating environments: extreme-temperature variants (-40°C to 70°C) for polar and desert regions, long-cycle (15,000+ cycles) versions for grid storage, and fast-charging optimized cells for ride-hailing fleets.

4. Sustainable Manufacturing

Localized production networks will expand, with CATL-style overseas factories reducing supply chain risks and carbon footprints. Recycling technologies will mature, targeting 95% recovery rates for lithium, nickel, and cobalt by 2030 to mitigate raw material volatility.

Conclusion

2025 represents a inflection point where battery technology transitions from performance-driven iteration to user-centric innovation. As sodium-ion batteries democratize electrification, solid-state technologies redefine performance limits, and AI accelerates innovation cycles, batteries are evolving from energy storage devices to “intelligent energy partners.” The next five years will see these technologies integrate deeply into transportation, grids, and renewable energy systems, laying the foundation for a fully decarbonized energy future.